» Detailing

• About Food Processing Plants

We are one of the foremost Traders and Manufacturers of a massive assortment of Food Processing Plants. The spacious assortment of systems offered by us include Pasteurizer, Juice process Line, Carbonator, SS Liquid mixing tank, SS pipe Lines and Fittings and Deep Fryer that are procured from Pune, Maharashtra, India.

Food Processing Plant:We fabricate these liquid milk processing plants and further Food Processing Plants which has capacity of managing 500 Ltrs/day to 3, 00, 000 Ltrs/day as well, milk intimidating plants 1000 Ltr/day to 1, 00, 000 Ltr/day which acquire into consideration milk function equipment chiller, pasteurizer and milk process line, storage facility, packing of milk & cold chain for end products. These products are energy proficient convenience services and all the plant machineries are interrelated mechanically and electrically most excellent production perform. We offer these food processing plants in numerous customizations.

• Juice Process Line:

We have expanded and sustain our well-built foothold in the production. Our prominent effectiveness and finest quality Juice Process Line is used in the beverage production. These are available in 1000 LPH specifications and are as per the industry quality standards and norms. These varieties are prominent for their properties such as supreme quality, longer service life, sky-scraping tensile strength and unyielding construction.

We take into account the miscellaneous requirements of our clients and offer the most suitable range of products. We offer this finest make Juice Process Line in comply with the international quality standards and norms set by the industry. Thus, this high grade Juice Process Line that is available with us is extensively praised in the industry for its consistency, robustness and incomparable performance.

Pasteuriser:

We made an extensive variety of meticulousness engineered Pasteurizers which are designed using latest mechanisms and highly developed technology. These pasteurizers have acknowledged incredible appreciation in the market for their robustness, performance and robust construction.

Technical Specifications

Rectangular tank with inclined bottom made up completely of stainless steel (SS • 304).

Function by gas burner unit.

• Engineered with four-leg retrenchment for impeccable balancing.

• The inner liner outer shell is made up of stainless steel with 2" glass wool insulation.

• Feature include high speed stirrer for the perfect blending of dry ingredients.

• Incorporated emulsifier with 2-speed motor.

• Regulate high temperature pasteurization at +85 oC and the low temperature pasteurization at +65oC.

• Temperature is indicated by digital temperature meter & heating medium by water.

Post Treatment Section

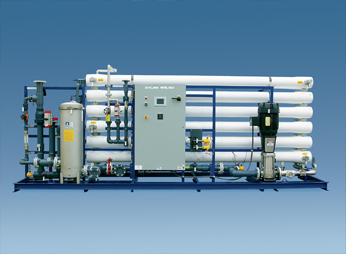

• Water Process Philosophy

Water treatment plant is designed to treat the water in various stages considering the different impurities shall be removed by different processes in various stages. Generically there are following three stages of treatment which has various processes to treat the particular impurity present in the water.

Pre-treatment Section

1. Coagulation by Alum dosing

2. Settling by Tube type or Plate type settler

3. Chlorination by Sodium Hypochlorite

4. Coarse Filtration (Sand or Multimedia filter)

5. Dechlorination by ACF or by dosing Sodium meta bisulphate

6. Ultra Filtration System

7. Antiscalant dosing system

8. Micron Filtration system

Main Treatment Section

1. Demineralization Plant

2. Reverse Osmosis Plant